Author: Rajan V K

In today’s fast-moving business world, data is no longer just a record of what happened yesterday, it’s a mirror that can reflect the present and even a crystal ball that can predict tomorrow. This is exactly where the power of Artificial Intelligence (AI) and Digital Twins comes in, and where Nexpert helps businesses turn these technologies into practical tools for smarter, faster, and more sustainable operations.

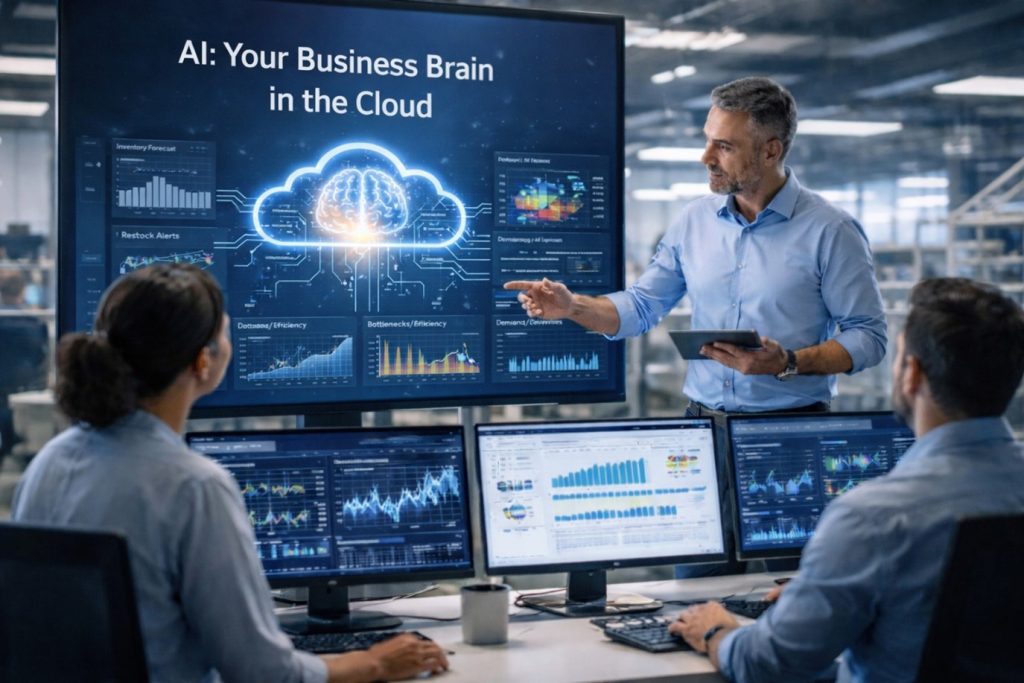

AI: The Brain That Learns from Your Business

Think of AI as a fast-learning assistant that never sleeps. It observes your company’s daily operations, learns from patterns, and starts giving suggestions, like when to restock, where bottlenecks are forming, or how to improve delivery schedules. For example, imagine your production line as a busy kitchen. AI watches how ingredients (data) are used, how long each dish (task) takes, and when supplies run low. Over time, it becomes smart enough to recommend recipes that save time, reduce waste, and improve consistency. AI helps companies make better decisions, but it mainly looks at data from the past and present. What if we could go one step further and test the future before it happens?

Digital Twin: The mirror world of your business from bridges to buildings, the smartest tool every industry will soon rely on

A few years ago, the idea of having a virtual copy of a physical object sounded futuristic. Today, digital twins are quietly becoming one of the most practical tools across industries, helping organizations see their assets in a new way. The strength of a digital twin lies in its simplicity: it allows us to understand the real world through a virtual model that stays connected to real-time data. Instead of guessing what might go wrong, organizations can observe issues forming in advance and make decisions with confidence. At Nexpert, our work with emerging technologies has found that digital twins are one of the most underrated yet powerful enablers for Industry 5.0, especially because they place humans, safety, and sustainability at the centre of technological progress.

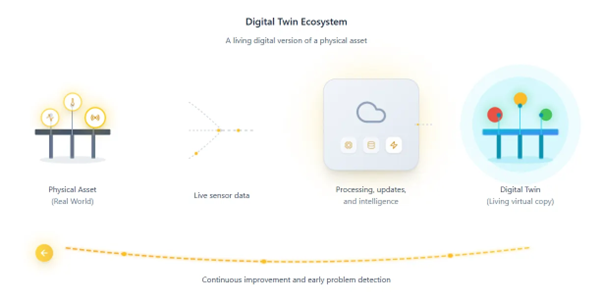

A digital twin is best understood as a living digital version of something physical: a bridge, a building, a machine or even a workspace. The virtual copy updates itself automatically as sensors generate new information. This creates a continuous flow from the physical environment to the digital representation, making it possible to spot problems early, visualize what is happening and explore better ways of working. What makes digital twins truly special is that they simplify complexity. Instead of long technical reports or inspection cycles, organizations get a clear visual model that reacts when conditions change. You can see a hotspot light up, observe structural stress, monitor temperature fluctuations or detect unusual vibrations long before they become expensive repairs.

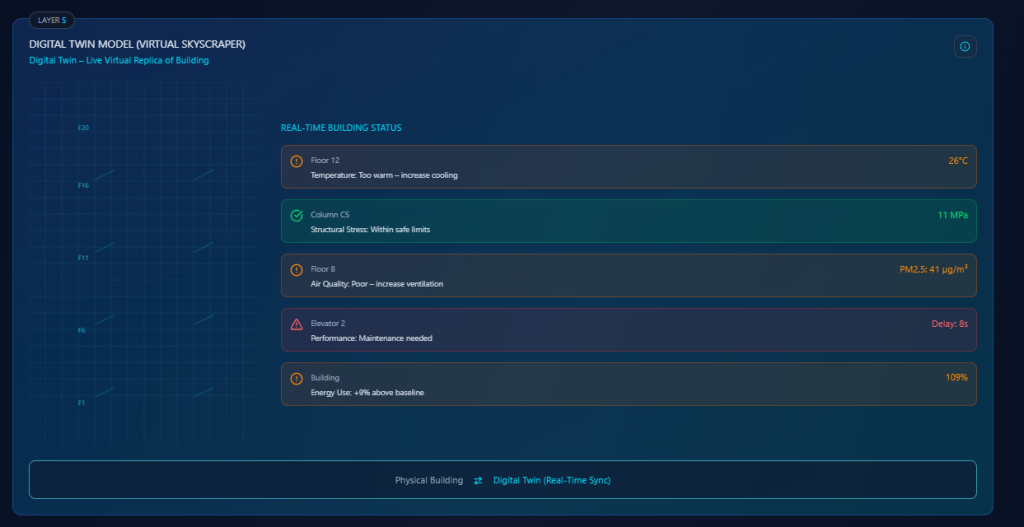

To understand how this works in practice, imagine a building under construction. Every day, the structure experiences subtle changes: concrete cures, temperatures rise and fall, humidity affects surfaces, heavy equipment moves and workers navigate evolving conditions. With a digital twin, these invisible processes become visible. Sensors placed on critical points send continuous information about stress, moisture and environmental conditions. The digital model updates itself, showing where curing might be slower, which areas need reinforcement or when vibration levels reach uncomfortable levels for worker safety. The builder does not have to wait for a delay or a problem to occur; the virtual model warns early and helps the team act at the right time (Please click this to see the core ideas behind it: 3D Skyscraper Digital Twin Simulation).

The same approach can transform the way bridges in the transportation sectors are maintained. A bridge normally requires expensive inspections and decades of manual experience to judge its condition. With a digital twin, even a simple set of low-cost sensors can reveal whether a structure is developing cracks, experiencing freeze–thaw damage or handling heavy traffic in a way that increases long-term stress. The digital model behaves like a continuous companion to the physical structure. When vibration frequency shifts slightly, it highlights the exact point on the bridge where stiffness has changed. If temperature and moisture levels rise in a vulnerable area, the model shows a potential risk zone. Engineers and decision-makers no longer rely on assumptions; they see the real behaviour of the bridge through a clear, intuitive interface.

One of the most interesting advantages of digital twins is that they support decision-making beyond maintenance. They help companies optimize their operations, reduce energy use, plan smarter schedules and improve sustainability performance. When the digital model learns how systems behave, it can also suggest better ways of working. For example, in a factory, it may recommend adjusting machine timing to reduce electricity consumption during peak hours. In a construction project, it may show how to sequence tasks for safer workflows. In public infrastructure, it can help determine the right moment for repairs, avoiding both premature maintenance and costly emergency interventions.

The value becomes even clearer when the cycle completes. Insights from the dashboard guide an action in the real world, a repair, a reinforcement, a parameter adjustment, a schedule change, and the physical improvement immediately appears in the digital model. This back-and-forth flow creates a closed loop where learning never stops. The twin continuously observes, analyzes and informs, while the organization continuously adapts and improves. In this way, digital twins fit perfectly within the vision of Industry 5.0, where technology supports human judgement instead of replacing it. Workers become more informed, environments become safer and operations become smoother, all while reducing costs and environmental impact.

Every industry can benefit from this transformation. Manufacturing lines can reduce downtime and improve output. Logistics operations can track movement in real-time and redesign workflows more intelligently. Construction companies can achieve safer and more predictable projects. Municipalities can maintain infrastructure more efficiently. Even small businesses can begin with simple, low-cost pilots using photogrammetry, affordable sensors and free cloud tools to build their first digital twin without major investment.

At Nexpert, our mission is to help organizations take these first steps with clarity and confidence. Digital twins do not have to be complicated or expensive to generate value. When combined with the right guidance, user-friendly tools and a human-centric perspective, they become a practical way to understand assets, optimize decisions and build sustainable, resilient operations for the future.

From Data to Decisions: The Power of AI and Digital Twins Together

AI and Digital Twin technologies complement each other perfectly.

If AI is the brain, the Digital Twin is the body it controls, together, they sense, learn, and act.

- AI analyses data and finds hidden patterns.

- The Digital Twin simulates actions based on those insights.

- The business learns continuously, improving speed, cost-efficiency, and sustainability.

This combination is transforming industries from manufacturing and logistics to construction and energy, by creating systems that can predict problems before they occur and optimise processes automatically.

The Challenge: Technology Without Strategy Is Just Noise

Many companies get excited about new digital tools but quickly realise that buying technology is not the same as transforming a business. What’s often missing is the strategy, understanding where, why, and how these technologies create value. That’s where consulting expertise becomes essential. Before building a digital twin or deploying AI, companies need to answer:

- What process problems are we solving?

- Do we have the right data?

- How will this technology fit into our people’s daily work?

- What performance goals are we trying to achieve?

Without these answers, digital tools can become expensive experiments instead of growth engines.

How Nexpert Helps Businesses Bridge the Gap

At Nexpert, we believe technology should serve strategy, not the other way around. Our mission is to help organizations take these first steps with clarity and confidence. Digital twins do not have to be complicated or expensive to generate value. When combined with the right guidance, user-friendly tools and a human-centric perspective, they become a practical way to understand assets, optimize decisions and build sustainable, resilient operations for the future. We help companies understand, plan, and implement AI and Digital Twin technologies as part of their long-term business improvement journey.

Here’s how we support our B2B clients:

- Education & Awareness

We simplify complex technologies through workshops and discussions, so leadership teams and employees understand what AI and Digital Twins really mean for their business.

- Strategy & Roadmapping

We identify where these technologies can create the most value whether in production efficiency, process transparency, or sustainability performance, and design a step-by-step roadmap for adoption.

- Implementation Partnerships

Nexpert collaborates with technology providers and research partners to bring the right digital tools to each client, ensuring solutions are practical, scalable, and aligned with their business goals.

- Performance Optimization & Continuous Learning

Once implemented, we help clients track results, integrate data-driven decision-making, and evolve their systems over time.

In short, we translate digital buzzwords into business results.

The Future Is Hybrid: Human Intelligence Meets Digital Foresight

Technology alone doesn’t create transformation, people who understand how to use it do. That’s why Nexpert’s mission is to empower organizations to merge human expertise with digital foresight. Whether you’re a manufacturing SME looking to optimize operations or a logistics company exploring predictive analytics, Nexpert can guide you from exploration to execution. The future of business process optimization isn’t about replacing people, it’s about augmenting human decisions with intelligent digital mirrors that see further, learn faster, and act smarter.

Let’s Co-Create Your Digital Future

At Nexpert, we don’t just talk about innovation, we make it actionable. Our team helps companies strategize, pilot, and scale AI and Digital Twin solutions that deliver measurable value. If you’re ready to explore how your business can see its operations in real time, test scenarios virtually, and make decisions with confidence, let’s start the conversation.

About the Author: Rajan Kumar V K is a Doctoral Researcher in the Department of Industrial Engineering and Management at the LENS School, LUT University, Finland. His research interests include performance measurement and management, novel technologies, digital transformation, sustainability, and innovation. He focuses on exploring how these areas are interrelated and how they influence each other in driving sustainable performance and supporting the future of Industry 5.0. He collaborates with Nexpert on built environment digital twins.

References:

Batty, M. (2018). Digital twins. Environment and Planning B: Urban Analytics and City Science, 45(5), 817-820.

Fernandez-Vidal, J., Perotti, F. A., Gonzalez, R., & Gasco, J. (2022). Managing digital transformation: The view from the top. Journal of Business Research, 152, 29-41. https://doi.org/10.1016/j.jbusres.2022.07.020

Franciosi, M., Kasser, M., & Viviani, M. (2024). Digital twins in bridge engineering for streamlined maintenance and enhanced sustainability. Automation in Construction, 168, 105834. https://doi.org/10.1016/j.autcon.2024.105834

Jasiński, M., Łaziński, P., & Piotrowski, D. (2023). The concept of creating digital twins of bridges using load tests. Sensors, 23(17), 7349. https://doi.org/10.3390/s23177349

Mazumder, A., Banerjee, P. S., Karmakar, A., Ghosh, P., De, D., & Song, H. (2023, February). Digital twin for industry 5.0: a vision, taxonomy, and future directions. In Doctoral Symposium on Human Centered Computing (pp. 246-259). Springer Nature Singapore. https://doi.org/10.1007/978-981-99-3478-2_22

Grieves, M., & Vickers, J. (2016). Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary perspectives on complex systems: New findings and approaches (pp. 85-113). Cham: Springer International Publishing. https://doi.org/10.1007/978-3-319-38756-7_4

Singh, M., Fuenmayor, E., Hinchy, E. P., Qiao, Y., Murray, N., & Devine, D. (2021). Digital twin: Origin to future. Applied System Innovation, 4(2), 36. https://doi.org/10.3390/asi4020036

Vial, G. (2021). Understanding digital transformation: A review and a research agenda. Managing digital transformation, 13-66. https://doi.org/10.4324/9781003008637

Ye, C., Butler, L., Bartek, C., Iangurazov, M., Lu, Q., Gregory, A., … & Middleton, C. (2019, September). A digital twin of bridges for structural health monitoring. In 12th International Workshop on Structural Health Monitoring 2019. Stanford University.

Contact Nexpert to discover how we can help you lead the next wave of digital transformation.

Leave a Reply